It is a beautiful way to teach recycling.

It is an intensive way to teach process control and engineering.

It is a fun way to allow the students to interact and produce a basic process line.

That is what Lynn Camp engineering teacher Hank Gevedon had to say about a recent integrated unit that combined the engineering class and the art class to make paper.

“For many years papermaking fascinated me. I had an opportunity to explore it deeply many years ago when I did an integrated unit with a high school art teacher. There are few projects which can combine recycling, a true art lesson, a great engineering lesson and still be fun,” said Gevedon who is in his second year of teaching at Lynn Camp.

“We take our daily use of paper for granted. However, the making of a sheet of paper that can be converted into a paper style packaging product is so overlooked and misunderstood by most people that they never get down into the real “nitty gritty” of how a sheet of paper is produced,” said Gevedon.

With his sights set on combining recycling, engineering, and art, Gevedon set out to make the lesson happen. Here he explains papermaking and how much fun it is.

I was fortunate to find an art teacher last year who was willing to do an integrated unit. An integrated unit is when two disciplines work together to expand and contribute to the effectiveness of a unit of study.

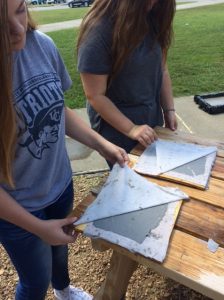

The art group and the engineering group were prepped at the same time and they understood all parts of the process. My engineering group developed the designs and the prints for the molds, the deckle, boards, and felts. The art group prepared to do some advance design work by adding things to the paper and to make colored papers. My engineering group did the pre-prep for the actual product.

The most fun is that it is very simple, fun, and inexpensive. It is a work of risk, not of certainty. The risk involved is that the person making the sheet of paper must reach into bath, pull up enough water and fiber to allow the sheet to settle properly, transfer the sheet to a felt, press, remove the sheet of paper from the felt, and take care of it while it is drying. In the end you produce a sheet of paper that is truly handmade.

The greatest thing is that we use recycled newspaper pulp which dissolves very easily. It produces a very tender sheet of paper but it shows the process very well, and lends itself to the engineering side in which my students continue the papermaking process by designing and building a wet molded paper container. They are not only required to produce two 8 1/2 sheets of deckle edged paper but also design and produce a paper container similar to the color and texture of an oldfashioned paper egg carton or the cup carriers currently use by fast food restaurants.

We begin the unit talking about recylcing and upcycling. We soak the paper until it is thouroughly moistened, run the newspaper print through grinders, mix the bath in which the fiber is suspended in water in preparation for making the sheets of paper.

One of the most enjoyable parts for me is the only way to describe the correct consistency of the bath is to have the students run their hands back and forth through it. If it is too thin, they can feel it. If it is too thick they can feel it. It is a great jumping off point to begin discussing the difficulties in the process of quality control.

From an engineering standpoint, the rest of the process is merely a series of pass or fail physical movements that allow successful production of a sheet of paper. Then we can look at the paper quality, paper thickness, troubleshoot points in the line having trouble with time and motion, and pinpoint segments of the process that need improvement.

The unit costs very little to make and if production of a sheet of paper is not correct it can be simply wiped off the screen, mixed into the bath, and do it again. The opportunity for students to do something over and over again until they are successful is really great.

The art side gets to produce the medium upon which they work. Handmade and custom papers are always exciting, interesting, and very inexpensive. I have had several students continue papermaking for several projects they have made after leaving high school and pursued their perspective field of art.

At the end of the unit, the results are always good and the activity is always fun. Gevedon said, “I’ve found that an integrated unit on papermaking to be an outstanding way to spend a few minutes outside doing something hands-on that the students take for granted but come to fully understand at the end of the process.”